Maintenance and troubleshooting of refrigeration compressor cold storage

Operational adjustment of the refrigeration system: Expansion valve is one of the four major components of the refrigeration system. It is an important device for regulating and controlling the flow and pressure of refrigerant entering the evaporator, and it is also the 'boundary line' between the high and low pressure sides. Its adjustment is not only related to the normal operation of the entire refrigeration system, but also an important indicator to measure the level of operator skills. For example, the measured cold storage temperature is -10°C, and the evaporation temperature is about 5°C lower than the maintenance cold storage temperature, that is, -15°C. According to the 'Refrigerant Temperature and Pressure Table' (taking R12 refrigerant as an example), the corresponding pressure is 0.23 MPa gauge pressure, this pressure is the adjustment pressure (outlet pressure) of the expansion valve.

Due to the pressure and temperature loss of the pipeline (depending on the length of the pipeline and the insulation effect), the suction temperature is 5-10℃ higher than the evaporation temperature, and the corresponding suction pressure should be 0.66~ 0.23MPa gauge pressure. Adjusting the expansion valve must be carried out carefully and patiently. Adjusting the pressure must pass through the heat exchange between the evaporator and the warehouse temperature, and then boil (evaporate) and then enter the compressor suction chamber through the pipeline to reflect on the pressure gauge. It takes a time process. Every time the expansion valve is adjusted, it usually takes 15-30 minutes to stabilize the adjustment pressure of the expansion valve on the suction pressure gauge. The suction pressure of the compressor is an important reference parameter for adjusting the pressure of the expansion valve. The opening degree of the expansion valve is small, the flow rate of the refrigerant passing through is small, and the pressure is also low; the opening degree of the expansion valve is large, the flow rate of the refrigerant passing through is more, and the pressure is also high. According to the thermal properties of the refrigerant, the lower the pressure, the lower the corresponding temperature; the higher the pressure, the higher the corresponding temperature. According to this law, if the outlet pressure of the expansion valve is too low, the corresponding evaporation pressure and temperature are also too low. However, due to the decrease of the flow into the evaporator and the decrease of the pressure, the evaporation speed slows down, the refrigeration capacity per unit volume (time) decreases, and the refrigeration efficiency decreases. On the contrary, if the outlet pressure of the expansion valve is too high, the corresponding evaporation pressure and temperature are also too high. The flow and pressure entering the evaporator are both increased. Due to the excessive liquid evaporation, the excessively humid gas (or even the liquid) is sucked into the compressor, causing the compressor's wet stroke (liquid hammer), making the compressor unable to work normally, causing a series of work The condition is bad and even damages the compressor. From this point of view, the correct adjustment of the expansion valve is particularly important for the operation of the system.

In order to reduce the pressure and temperature loss after the expansion valve is adjusted, the expansion valve should be installed as far as possible on the horizontal pipe away from the maintenance entrance of the cold storage, and the temperature sensing bulb should be wrapped on the side of the air return pipe (low pressure pipe) Central location. When the expansion valve is in normal operation, the valve body is slanted with frost, and the inlet side should not be frosted, otherwise it should be regarded as an ice block or dirty block in the inlet filter. Under normal circumstances, the expansion valve is very quiet when it is working. If there is a more obvious 'silk' sound, it means that the refrigerant in the system is insufficient. The expansion valve should be replaced when the temperature sensing system leaks or fails to adjust.

1. The cold storage refrigeration compressor accidentally stops running or the cooling capacity drops suddenly. Common reasons are:

The motor cannot start, mainly due to the power supply circuit, the control circuit and the motor itself. Fault. The motor can't move, mainly caused by compressor bite or valve leakage. Sudden stop during operation is mainly caused by low suction pressure, high exhaust pressure, low lubricating oil pressure, and motor overload. Insufficient refrigeration capacity is mainly caused by too thick frosting on the evaporator, poor sealing and insulation performance of the freezer, too much flow of the expansion valve, air in the system, too much refrigerant charge, poor filter, blocked expansion valve, refrigeration Caused by insufficient agent, oil in the evaporator, etc. No refrigeration; mainly caused by the inability of the refrigerant to circulate in the system. The compressor itself is malfunctioning. After the refrigeration system fails, it must be checked in sections to find out the cause and take appropriate measures to eliminate it.

2. Frozen blocking: also known as 'ice blocking'. The phenomenon in which liquid freezing substances [such as ice] hinder the flow of refrigerant in a Freon refrigeration system. Often occurs in throttling mechanisms. When the water content exceeds the specified standard [such as the water content of R12 ex-factory products, the water content should be less than 0.0025%]. When the freon flows through the throttling mechanism, the temperature drops due to the throttling and pressure reduction. The part of the water that is dissolved in Freon due to the decrease in solubility] may form ice at the throttling part or completely block the throttling valve hole or capillary channel. As a result, the Freon flow rate in the system decreases sharply, the suction and exhaust pressures drop, and the refrigeration capacity drops. Even the Freon cannot pass through, and the refrigeration device cannot work normally. The judgment method is to heat with fire outside the throttling mechanism. If the above phenomenon can be eliminated after heating, it is freezing blockage, otherwise it is dirty blockage. The method to eliminate freezing: remove the water in the freon, and replace the original desiccant or dryer. To lower the freezing point of water, you can add a small amount of methanol to the system to dissolve it with water. But this is an emergency measure when there is no hygroscopic equipment and cannot be used easily. When too much methanol is added to the system, it will cause changes in the nature of the refrigerant, resulting in a decrease in the cooling capacity, which will also affect the cooling effect, and will also cause chemical corrosion, copper plating or the motor winding of the fully enclosed compressor is broken down and burned. Seriously affect the normal and safe operation of the system.

Hangzhou E cool refrigeration Co.,Ltd is one of the world’s leading and most-trusted suppliers to the relevant markets.

You will find a wide variety of for sale for virtually any start capacitor suppliers needs. Keep in mind how you plan to use the , and talk with a professional about the model and features that are right for your application. Go to Arkool Refrigeration for on sale.

Hangzhou E cool refrigeration Co.,Ltd is the best manufacturer which has rich experience on manufacturing.

Visit Arkool Refrigeration to find recent dynamics of air conditioner capacitor and contact Hangzhou E cool refrigeration Co.,Ltd for the latest and most capable in global market.

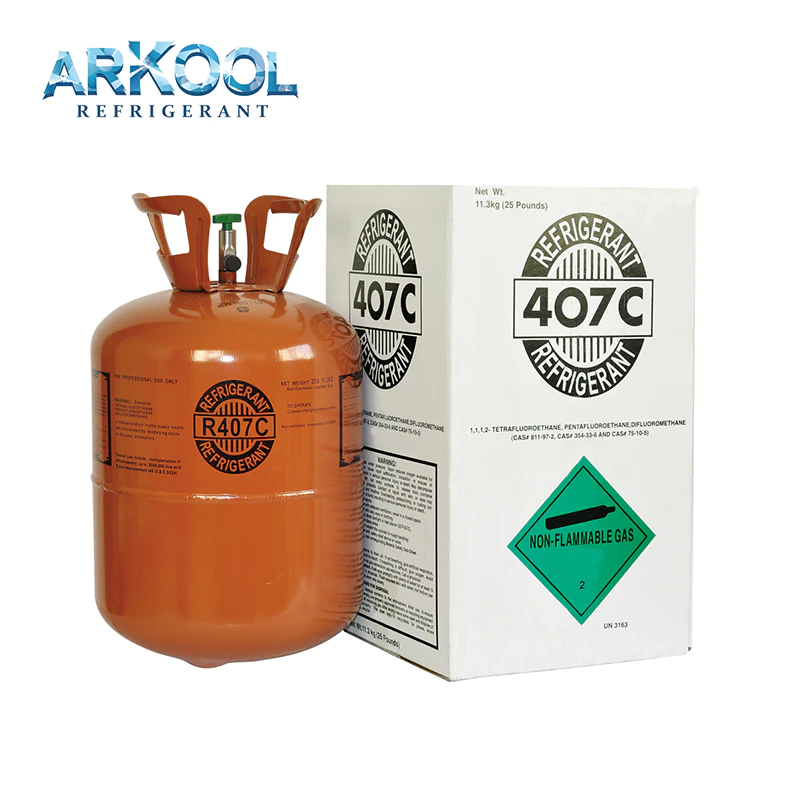

refrigerant gas has its grasp on oversees market also and has a very good repute.